Feed dust collector equipment

Feed dust collector equipment

1. High efficiency and stability, simple maintenance.

2. Simple operation, environmental protection and energy saving.

3. High safety.

4. Wide adaptability and low noise.

5. Wide range of applications and long service life.

Support customization of various models

Product Introduction

Product Overview:

Feed dust collector is a device that separates dust from flue gas. The performance of dust collector is expressed by the amount of gas that can be processed, the resistance loss when the gas passes through the dust collector, and the dust removal efficiency. At the same time, the price, operation and maintenance costs, service life and difficulty of operation and management of the dust collector are also important factors to consider its performance. Dust collector is a commonly used facility in boilers and industrial production. A dust hood is set at each place where dust is emitted, and the dust-containing gas is transported to the dust removal device through the pipeline gas path. After gas-solid separation, the dust is collected in the dust removal device, and the clean gas is introduced into the main pipe or directly discharged into the atmosphere. The whole set of equipment is the dust removal system, and the dust collector is an important component of the system. From the perspective of ventilation and dust removal, dust is all small solid particles that can exist in the air in a floating state for a long time. It is a dispersed system called aerosol, in which air is the dispersion medium and solid particles are the dispersed phase. The dust collector is a device that separates such small solid particles from the aerosol. Users need to choose the appropriate model according to their needs, and pay attention to follow the operating procedures to ensure the safety and stable operation of the equipment.

Scope of application:

Feed dust collectors are widely used in many industries, including but not limited to metallurgy, mining, building materials, casting, chemicals, tobacco, electronics, asphalt, cement, machinery, grain processing, boilers, flour production, etc.

Main features:

1. High efficiency and stability, simple maintenance.

2. Simple operation, environmental protection and energy saving.

3. High safety.

4. Wide adaptability and low noise.

5. Wide range of applications and long service life.

Application:

1. Used to separate dust from flue gas and purify the air.

2. In order to reduce air pollution and protect the atmospheric environment.

3. Various models of equipment can be processed according to customer requirements.

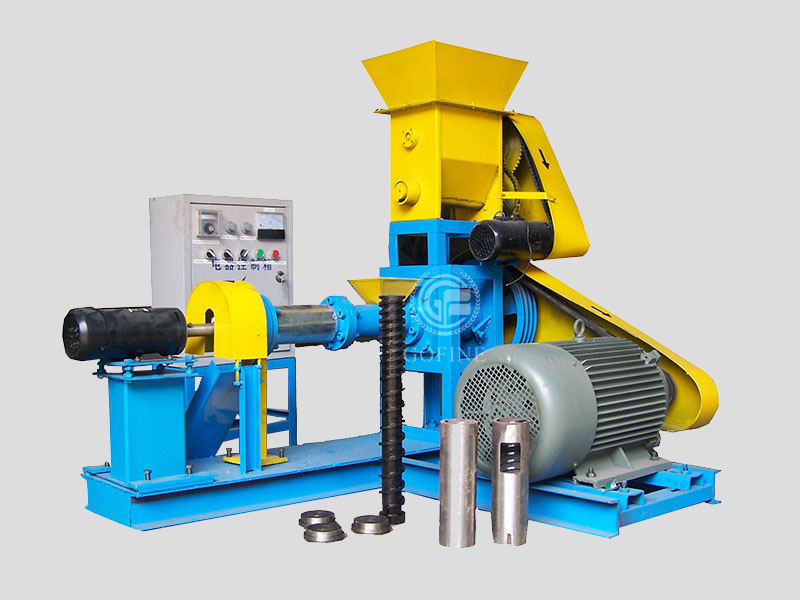

Product Pictures

Service Process

Pre-sales Service

1. Provide comprehensive technical and business consulting services.

2. Propose the most suitable solutions and equipment for customers.

3. Design and produce machines according to the special requirements of customers.

After-sales Service

1. Carefully check every process of the machine, quality first.

2. Assist customers in equipment infrastructure construction.

3. Dispatch engineers to install and debug equipment, and train front-line operators on site.

4. Regularly visit customers to solve production problems and provide technical support.

Feed dust collector is a device that separates dust from flue gas, called dust collector or dust removal equipment. It is a device used in industrial production to reduce the concentration of suspended particles in the gas. The basic working principle of the dust collector is to pass the gas containing suspended particles through the dust removal equipment, and filter or settle the particles from the airflow through mechanical or electrical action to achieve the purpose of purifying the air and protecting the environment. Different types of dust collectors use different principles, but they all achieve their goals by separating, filtering, and cleaning the particles in the gas. Dust collectors mainly include mechanical, wet, electrostatic, filter bag, cyclone, and electrostatic dust collectors.

Videos:

Prev: Feed electric control cabinet Next:NULL

Related Products

Feed seasoning machine

Product Overview: Feed seasoning machine is a special equipment that improves the taste and smell of feed by fully mixing various seasonings with feed. It can improve the palatability of feed, stimulate the appetite of animals, make animals more willing to eat, and thus promote the growth and production performance of animals. Scope of application: Livestock and poultry farming, aquaculture, pet food processing Main features: 1. High mixing uniformity: It can make the seasoning evenly distribut…

Floating feed pellet machine

Product Overview: The Floating feed pellet machine is based on mechanical circular motion. The motor is used as the power to drive the belt pressure wheel to transmit to the main shaft and the flat die, so that the pressure wheel and the die plate are compressed and rubbed. The material is squeezed out from the flat die hole under the pressure of the pressure wheel, and the pellet feed is rolled out after being segmented by the cutter. It is packaged after natural cooling. This multifunctional …

Feed powder packaging machine

Product Overview: Feed powder packaging machine is a kind of equipment specially designed for packaging powdered or granular feed. Feed powder packaging machine mainly includes the following parts: feeding device, metering device, packaging material supply device and packaging forming device. Its working principle is: the granular material is transported to the metering device through the feeding device, the metering device weighs according to the preset parameters, and then the weighed granula…