Feed Pellet Machine

Feed pellet machine is a professional equipment that can efficiently convert various feed raw materials into high-quality pellet feed. It can make pellet feed for pigs, cattle, sheep, chickens, ducks, geese, fish, birds, cats, dogs and other animals. The pellet feed produced has a balanced combination of different nutrients and is an important equipment in the animal husbandry industry.

Animal feed pellet machine is the core equipment in the process of breeding modernization. It is popular for its high efficiency, high quality, diversity and convenience. According to the working principle of animal feed pellet machine, it can be divided into flat die pellet machine, ring die pellet machine and Floating feed pellet machine. If you want to know more about the product, you can contact us directly.

Ring die feed pellet machine:

Ring die feed pellet machine

Model: GF-35

Capacity: 1-8(t/h)

Power: 30-75(kw)

Ring mould aperture: 2mm-18mm

Scope of application: Feed mills, livestock farms, breeding farms, etc.

Raw materials: corn, soybean meal, straw, grass, rice husk, etc.

Ring die feed pellet machine: mainly composed of ring die and pressure roller. The ring die is a rotating part with many evenly distributed die holes, and the pressure roller fits closely with it inside the ring die. When the material enters the working area between the ring die and the pressure roller, as the ring die rotates, the pressure roller squeezes the material into the die hole of the ring die, and the material is squeezed out of the die hole to form particles.

Advantages: high production efficiency, can continuously and stably produce high-quality particles. The particles have a large density, a smooth surface, and good appearance quality. This is because the material can be fully compacted and formed through the die hole under the strong extrusion force of the ring die and the pressure roller.

Flat die feed pellet machine:

Flat die feed pellet machine: It consists of a flat die and a pressure roller. The flat die is a flat disc with a die hole. The pressure roller rolls on the surface of the flat die to squeeze the material into the die hole of the flat die to form pellets.

Features: simple structure, relatively low price, easy maintenance. It is suitable for small farms or home use and can process a variety of feed raw materials, such as grains, grass powder, etc. .

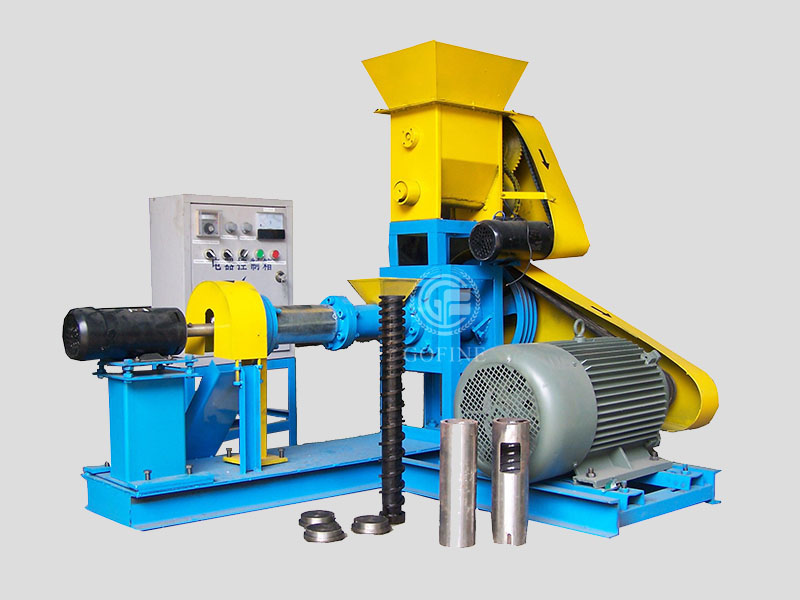

Extruded feed pellet machine:

Extruded feed pellet machine: Through the rotation of the screw or spiral shaft, the material is pushed forward and squeezed out of the die hole to form pellets. The material is subjected to strong extrusion force in the barrel, and is gradually compacted and formed as the screw rotates.

Features: This pellet machine has a relatively simple structure, is easy to operate, and is suitable for pelletizing a variety of materials. It can process some materials with a certain fiber content and has strong adaptability to materials.

Videos: