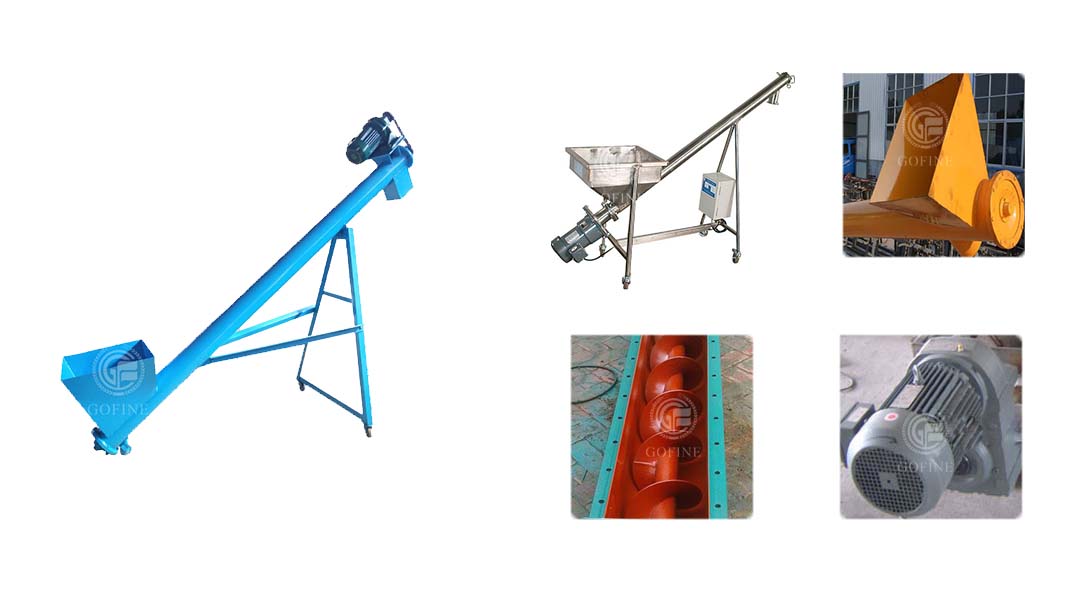

Feed spiral elevator

Feed spiral elevator

1. High efficiency and stability, simple structure.

2. Simple operation, environmental protection and energy saving.

3. Small space occupation.

4. High conveying efficiency and high lifting height.

5. Wide range of application and long service life.

Support customization of various models

Product Introduction

Product Overview:

Feed spiral elevator is one of the common mechanical equipment in animal husbandry. The working principle of the spiral elevator mainly depends on the rotation of the spiral blade. When the spiral shaft rotates, the spiral blade will rotate accordingly. This rotational motion pushes the material from the bottom to the top. Under the push of the spiral blade, the material forms a certain upward movement speed in the spiral tube, thereby realizing the vertical transportation of the material. It provides effective help for feed transportation on the production line, improves production efficiency and reduces labor costs. At the same time, it can also effectively avoid the waste and pollution of raw materials, improve product quality and environmental protection standards. In addition, the bucket elevator has low maintenance costs and a long service life.

Scope of application:

Feed spiral elevator is suitable for lifting and loading of food, medicine, chemical industry, plastics, farms, and feed processing plants.

Main features:

1. High efficiency and stability, simple structure.

2. Simple operation, environmental protection and energy saving.

3. Small space occupation.

4. High conveying efficiency and high lifting height.

5. Wide range of application and long service life.

Application:

1. Used for lifting and transporting materials from low to high.

3. Various models of equipment can be processed according to customer requirements.

Product Pictures

Service Process

Pre-sales Service

1. Provide comprehensive technical and business consulting services.

2. Propose the most suitable solutions and equipment for customers.

3. Design and produce machines according to the special requirements of customers.

After-sales Service

1. Carefully check every process of the machine, quality first.

2. Assist customers in equipment infrastructure construction.

3. Dispatch engineers to install and debug equipment, and train front-line operators on site.

4. Regularly visit customers to solve production problems and provide technical support.

The main purpose of feed distribution cabinet is to provide power distribution and control for electrical equipment of feed production line. In the feed production process, a variety of electrical equipment such as motors, sensors, and controllers are involved. These devices require a stable power supply to ensure the normal operation of the production line.

Videos:

Prev: Vertical feed countercurrent cooler Next: Feed bucket elevator

Related Products

Feed pellet mesh belt dryer

Product Overview: Feed pellet dryer is a machine that evenly spreads feed pellets on a mesh belt through a feeding device. The mesh belt moves slowly under the drive of a transmission device, so that the feed pellets are transported from the feeding end to the discharging end. During the transportation process, hot air enters the drying chamber from the bottom or side of the dryer, fully contacts the feed pellets, and evaporates the moisture in the feed pellets into water vapor through heat tra…

Powdered feed production line

Product Overview: The powdered feed production line is a highly automated feed production equipment that integrates multiple process flows such as raw material crushing, mixing, pressing and molding to produce high-quality pellet feed efficiently and accurately. This production line is designed to meet the modern breeding industry’s demand for efficient, accurate and high-quality feed. The powdered feed production line is usually composed of multiple key equipment, such as feed crusher, f…

Feed oil adding equipment

Product Overview: Feed oil and fat adding equipment is mainly used to add oil, molasses, lysine, fish paste and other nutrients in the feed production process to improve the subsequent processing performance and feed quality. This type of equipment is usually suitable for batch mixers Scope of application: Livestock and poultry feed production, aquatic feed production, pet feed production. Main features: 1. Accurate metering: The general metering accuracy can reach an error range of ±0.5% to ±1…