Animal feed processing machinery manufacturer

Animal feed processing machinery manufacturer

1. Main types

Feed pelleting machine

Function: Mix the feed raw materials into granular feed by extrusion, heating and other methods. Granular feed has the advantages of good stability, not easy to grade, easy to transport and store, and is also conducive to animal feeding and digestion.

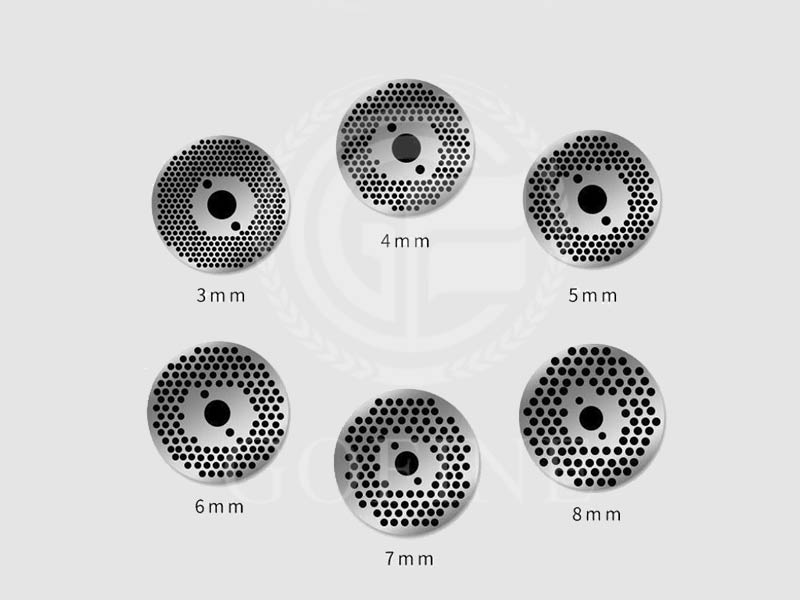

Features: The size and hardness of the particles can be adjusted according to the needs of different animals.

Feed extruder

Function: After the feed is treated with high temperature and high pressure, it is suddenly decompressed to expand the feed and form a porous structure. The extruded feed has better taste and digestibility, especially suitable for young animals and aquatic animals.

Features: It can improve the palatability and nutritional utilization of feed.

2. Important role

Improve production efficiency

Feed processing machinery can process a large amount of feed raw materials quickly and efficiently, greatly shortening the time of feed production and meeting the needs of large-scale breeding.

Equipment with a high degree of automation can run continuously, reduce manual operation and reduce labor intensity.

Ensure feed quality

Precisely control the composition and proportion of the feed to ensure the nutritional balance of the feed and meet the nutritional needs of animals at different growth stages.

Improve the physical properties of feed and increase the animal’s feeding rate and digestion and absorption rate through processes such as crushing, mixing, and granulation.

Reduce costs

Reasonably utilize various feed resources, such as crop by-products and waste, to reduce feed costs.

Reduce feed waste and improve feed utilization.

3. Development trend

Intelligence

Feed processing machinery Equipped with advanced sensors and control systems to achieve automated production and remote monitoring. It can monitor the equipment’s operating status, feed quality parameters, etc. in real time, and automatically adjust and optimize.

Use artificial intelligence technology for fault diagnosis and predictive maintenance to improve equipment reliability and stability.

Energy saving and environmental protection

Use energy-saving technology to reduce equipment energy consumption. For example, optimize the motor drive system, improve thermal efficiency, etc.

Reduce dust and noise pollution and meet environmental protection requirements. At the same time, effectively treat and utilize waste in the feed processing process.

Multifunctionality

One device can achieve multiple functions, such as crushing, mixing, granulation, puffing, etc., to improve equipment utilization and flexibility.

Feed processing machinery Adapt to the processing needs of different types of animal feed and meet diverse market needs.

Prev: Chicken, duck and other poultry feed production line Next: Efficient sheep feed production line solution