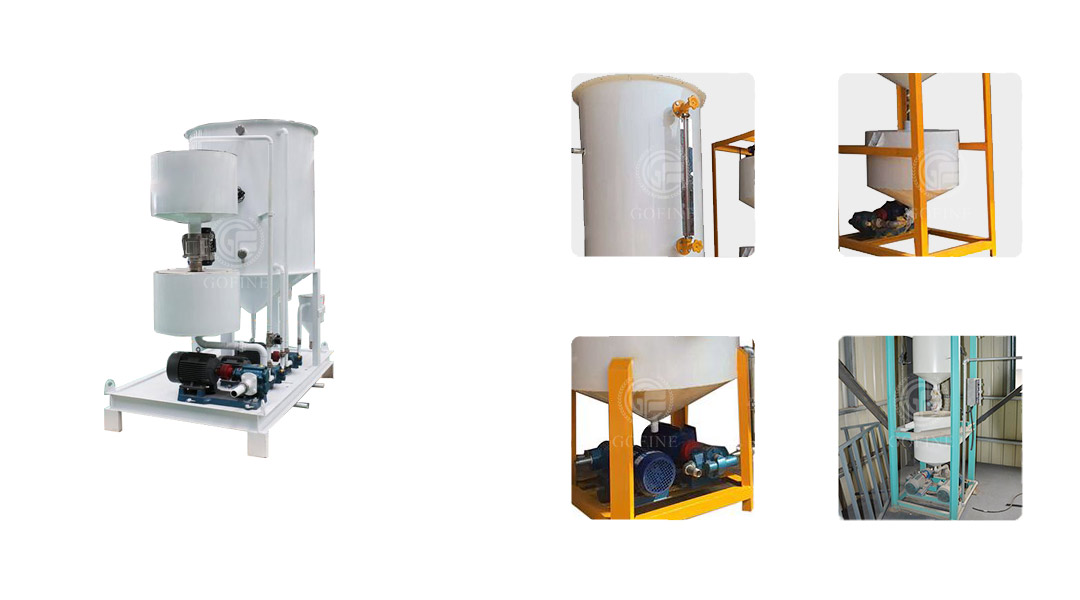

Feed oil adding equipment

Feed oil adding equipment

Feed oil and fat adding equipment is mainly used to add oil, molasses, lysine, fish paste and other nutrients in the feed production process to improve the subsequent processing performance and feed quality. This type of equipment is usually suitable for batch mixers

Product Introduction

Product Overview:

Feed oil and fat adding equipment is mainly used to add oil, molasses, lysine, fish paste and other nutrients in the feed production process to improve the subsequent processing performance and feed quality. This type of equipment is usually suitable for batch mixers

Scope of application:

Livestock and poultry feed production, aquatic feed production, pet feed production.

Main features:

1. Accurate metering: The general metering accuracy can reach an error range of ±0.5% to ±1%, ensuring the stability and uniformity of the fat content in the feed.

2. Even mixing: Through special adding devices and mixing processes, the palatability and digestibility of the feed are improved.

3. Wide range of applications: Various types of fats can be added, such as vegetable oil, animal oil, fish oil, etc., and can adapt to different feed production scales and process requirements.

4. High degree of automation: It can realize linkage control with other equipment on the feed production line to improve production efficiency and product quality stability.

5. Hygiene and safety: The equipment is made of food-grade stainless steel, meets hygiene standards, and ensures the hygiene and safety of the feed.

Application:

It is suitable for the production and processing of various types of animal feed, such as livestock and poultry feed, aquatic feed, pet feed, etc. It can add different types and proportions of oils and fats according to the nutritional needs and feed formulas of different animals.

Service Process

Pre-sales Service

1. Provide comprehensive technical and business consulting services.

2. Propose the most suitable solutions and equipment for customers.

3. Design and produce machines according to the special requirements of customers.

After-sales Service

1. Carefully check every process of the machine, quality first.

2. Assist customers in equipment infrastructure construction.

3. Dispatch engineers to install and debug equipment, and train front-line operators on site.

4. Regularly visit customers to solve production problems and provide technical support.

Videos:

Prev: Commercial stainless steel meat grinder Next: Feed pellets vertical dryer

Related Products

Vertical feed mixer

Product Overview: Vertical feed mixer is a kind of mechanical equipment commonly used in feed production. Its structure mainly consists of cutting structure, motion mechanism and mixing structure. Through the cooperation of these structures, the work of fully mixing and stirring the feed is completed. The feed mixer adds the materials to be mixed from the lower feed port, and the lifting screw in the feed mixer moves the mixing materials from the feed hopper of the vertical mixer into the verti…

Feed oil adding equipment

Product Overview: Feed oil and fat adding equipment is mainly used to add oil, molasses, lysine, fish paste and other nutrients in the feed production process to improve the subsequent processing performance and feed quality. This type of equipment is usually suitable for batch mixers Scope of application: Livestock and poultry feed production, aquatic feed production, pet feed production. Main features: 1. Accurate metering: The general metering accuracy can reach an error range of ±0.5% to ±1…

Small household feed pellet production line

Product Overview: The small feed pellet production line is a highly automated feed production equipment that integrates multiple process flows such as raw material crushing, mixing, pressing and molding to produce high-quality pellet feed efficiently and accurately. This production line is designed to meet the needs of modern aquaculture for efficient, accurate and high-quality feed. The pellet feed production line usually consists of multiple key equipment, such as feed crusher, feed mixer, fe…