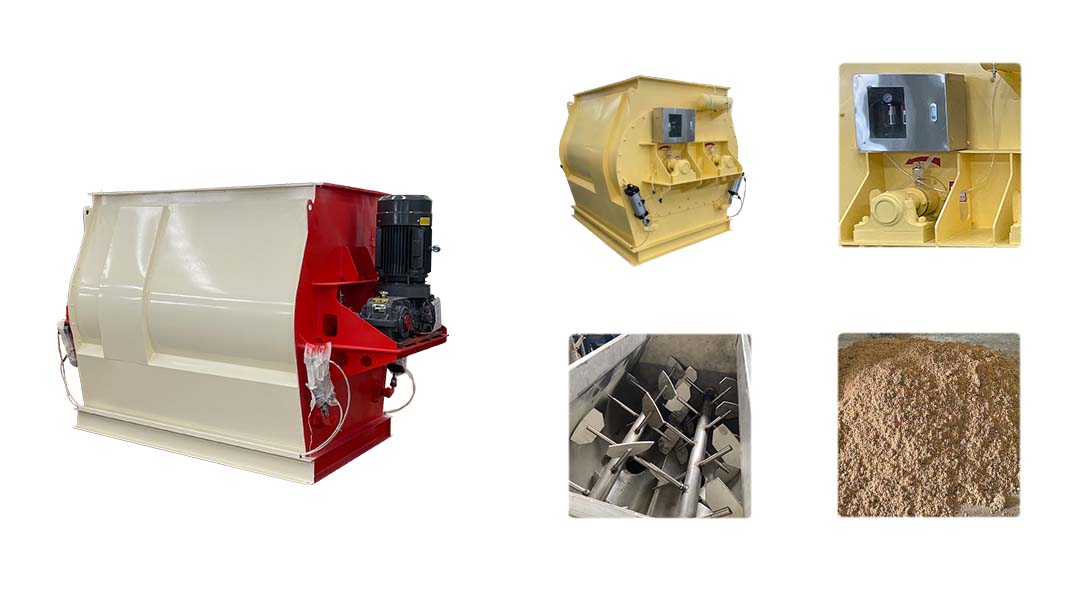

Double shaft zero gravity mixer

Double shaft zero gravity mixer

1. Efficient and stable, uniform mixing.

2. Simple operation, energy saving and environmental protection.

3. Easy maintenance and durable.

4. Wide range of application and long service life.

Support customization of various models

Product Introduction

Product Overview:

Double-axis gravity-free feed mixer is a kind of mechanical equipment commonly used in feed production. When the material in the machine is subjected to the action of two oppositely rotating rotors, it performs compound motion. A weightless zone is formed at the intersection of the two rotors. In this zone, no matter what the shape, size and density of the material is, the material can float up and be in a state of instant weightlessness, which makes the material form a full-range continuous flipping in the machine trough, and shears each other staggered, so as to achieve a fast and gentle, uniform mixing effect.

Scope of application:

Widely used in the drying and mixing of powder materials such as dry mortar, chemicals, pesticides, detergents, pigments, foods, monosodium glutamate, milk powder, salt, feed, chemicals, ceramics, plastics, rubber additives, etc.

Main features:

1. Efficient and stable, uniform mixing.

2. Simple operation, energy saving and environmental protection.

3. Easy maintenance and durable.

4. Wide range of application and long service life.

Application:

1. Used for mixing and stirring various raw materials such as grain, bean cake, corn cake, fish meal, protein powder, additives, etc.

2. It can mix and stir various powders and granular feeds.

3. Various types of equipment can be processed according to customer requirements.

Technical Parameters

| Model | Power(kw) | Capacity(m³) | Each batch(kg) | Mixing uniformity(cv%) | Mixing time(m) |

| SJB0.5 | 5.5 | 0.5 | 250 | ≤5 | 30-120 |

| SJB1 | 11 | 1 | 500 | ≤5 | 30-120 |

| SJB2 | 18.5 | 2 | 1000 | ≤5 | 30-120 |

| SJB4 | 30 | 4 | 2000 | ≤5 | 30-120 |

Product Pictures

Service Process

Pre-sales Service

1. Provide comprehensive technical and business consulting services.

2. Propose the most suitable solutions and equipment for customers.

3. Design and produce machines according to the special requirements of customers.

After-sales Service

1. Carefully check every process of the machine, quality first.

2. Assist customers in equipment infrastructure construction.

3. Dispatch engineers to install and debug equipment, and train front-line operators on site.

4. Regularly visit customers to solve production problems and provide technical support.

Feed mixers are mainly used for mixing and stirring various feeds. Feed mixers play a role in mixing, crushing, improving solubility and sanitation and safety during feed processing, which can improve the quality and nutritional value of feed and meet the nutritional needs of animals. According to different processes, feed crushers can be divided into horizontal mixers, vertical mixers, double-shaft zero-gravity mixers, etc. Various feed mixers are widely used.

Videos:

Prev: Vertical feed mixer Next: Horizontal feed mixer

Related Products

Floating feed pellet production line

Product Overview: The floating feed pellet production line is a highly automated feed production equipment that integrates multiple process flows such as raw material crushing, mixing, pressing and molding to produce high-quality pellet feed efficiently and accurately. This production line is designed to meet the needs of modern aquaculture for efficient, accurate and high-quality feed. The pellet feed production line usually consists of multiple key equipment, such as feed crusher, feed mixer,…

Household Carbon Steel Meat Grinder

Product Overview: The household carbon steel meat grinder puts the cut meat or other ingredients into the feed port. After the power is turned on, the motor drives the screw propeller to rotate and slowly pushes the ingredients to the reamer. The reamer cuts and crushes the ingredients during the high-speed rotation. The crushed ingredients are squeezed out through the small holes on the meat outlet plate to form minced meat or minced food of the required coarseness and fineness, which are disc…

Powdered feed production line

Product Overview: The powdered feed production line is a highly automated feed production equipment that integrates multiple process flows such as raw material crushing, mixing, pressing and molding to produce high-quality pellet feed efficiently and accurately. This production line is designed to meet the modern breeding industry’s demand for efficient, accurate and high-quality feed. The powdered feed production line is usually composed of multiple key equipment, such as feed crusher, f…