Feed seasoning machine

Feed seasoning machine

Feed seasoning machine is a special equipment that improves the taste and smell of feed by fully mixing various seasonings with feed. It can improve the palatability of feed, stimulate the appetite of animals, make animals more willing to eat, and thus promote the growth and production performance of animals.

Product Introduction

Product Overview:

Feed seasoning machine is a special equipment that improves the taste and smell of feed by fully mixing various seasonings with feed. It can improve the palatability of feed, stimulate the appetite of animals, make animals more willing to eat, and thus promote the growth and production performance of animals.

Scope of application:

Livestock and poultry farming, aquaculture, pet food processing

Main features:

1. High mixing uniformity: It can make the seasoning evenly distributed in the feed, ensuring that each grain of feed can fully absorb the taste of the seasoning and improve the palatability of the feed.

2. High seasoning accuracy: The use of advanced metering devices can accurately control the amount of seasoning added to meet the needs of different feed formulas.

3. Wide range of applications: It can be used for various types of feed, such as powdered feed, pellet feed, puffed feed, etc.

4. High degree of automation: It has an automated control system, which is simple and convenient to operate, reduces manual intervention, and improves production efficiency.

5. Good hygienic performance: It is made of high-quality stainless steel materials, which is easy to clean and maintain, and meets the hygienic requirements of feed production.

Application:

Whether it is powdered feed, pellet feed or extruded feed, the feed seasoning machine can effectively season it. For feeds of different shapes, sizes and densities, you only need to adjust the corresponding working parameters to achieve the ideal seasoning effect.

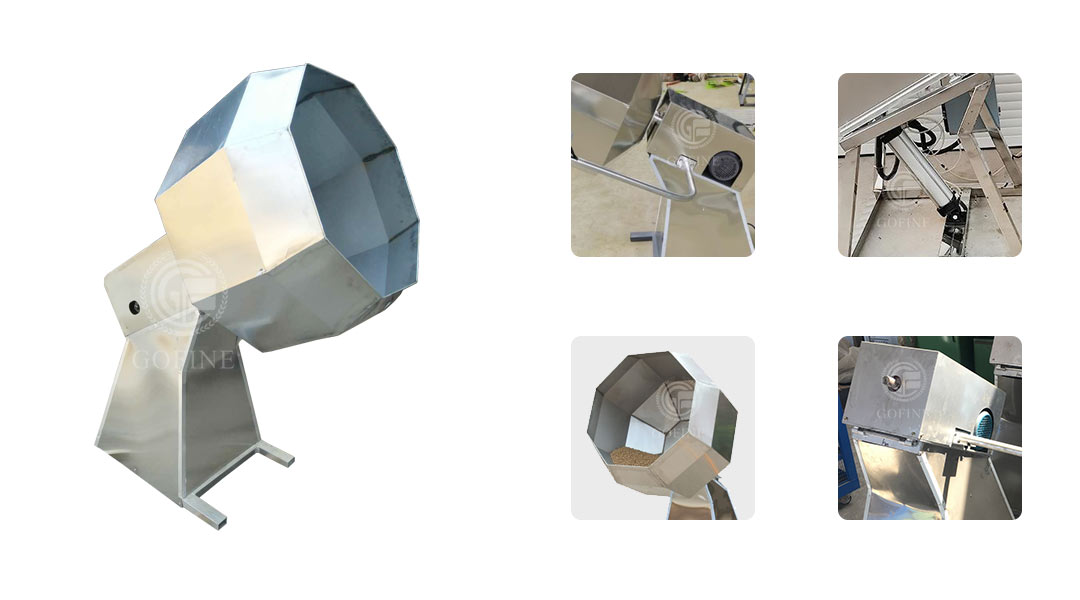

Product Pictures

Service Process

Pre-sales Service

1. Provide comprehensive technical and business consulting services.

2. Propose the most suitable solutions and equipment for customers.

3. Design and produce machines according to the special requirements of customers.

After-sales Service

1. Carefully check every process of the machine, quality first.

2. Assist customers in equipment infrastructure construction.

3. Dispatch engineers to install and debug equipment, and train front-line operators on site.

4. Regularly visit customers to solve production problems and provide technical support.

Videos:

Prev: Feed pellet mesh belt dryer Next:NULL

Related Products

Vertical feed countercurrent cooler

Product Overview: The feed vertical counterflow cooler is mainly used to cool high-temperature pellets after pelleting. The most advanced pellet feed cooling technology in the world, a new generation of cooling equipment developed by research and development, is mainly used to fully and evenly cool high-temperature pellet feed after pelleting. It adopts a unique slide valve mechanism to discharge materials, with stable operation and smooth discharge. The medium of the horizontal cooler flows fr…

Double shaft zero gravity mixer

Product Overview: Double-axis gravity-free feed mixer is a kind of mechanical equipment commonly used in feed production. When the material in the machine is subjected to the action of two oppositely rotating rotors, it performs compound motion. A weightless zone is formed at the intersection of the two rotors. In this zone, no matter what the shape, size and density of the material is, the material can float up and be in a state of instant weightlessness, which makes the material form a full-r…

Feed seasoning machine

Product Overview: Feed seasoning machine is a special equipment that improves the taste and smell of feed by fully mixing various seasonings with feed. It can improve the palatability of feed, stimulate the appetite of animals, make animals more willing to eat, and thus promote the growth and production performance of animals. Scope of application: Livestock and poultry farming, aquaculture, pet food processing Main features: 1. High mixing uniformity: It can make the seasoning evenly distribut…