Horizontal feed countercurrent cooler

Horizontal feed countercurrent cooler

1. Highly efficient, stable and simple in structure.

2. Easy to install, environmentally friendly and energy-saving.

3. The cooling effect is significant.

4. Convenient for material observation and maintenance.

5. Wide application range and long service life.

Support customization of various models

Product Introduction

Product Overview:

The feed horizontal counterflow cooler is mainly used to cool high-temperature pellets after pelleting. The most advanced pellet feed cooling technology in the world, a new generation of cooling equipment developed by research and development, is mainly used to fully and evenly cool high-temperature pellet feed after pelleting. It adopts a unique slide valve mechanism to discharge materials, with stable operation and smooth discharge. The medium of the horizontal cooler flows from bottom to top, and then contacts the upper material, which is a counter-current cooling. The material layer height and material stop time of the horizontal cooler are adjustable, and the material layer thickness is relatively uniform, allowing for flexible selection of appropriate cooling conditions.

Scope of application:

Feed counterflow cooler is suitable for breeding farms and feed processing plants.

Main features:

1. Highly efficient, stable and simple in structure.

2. Easy to install, environmentally friendly and energy-saving.

3. The cooling effect is significant.

4. Convenient for material observation and maintenance.

5. Wide application range and long service life.

Application:

1. Used for material cooling.

2. Various types of equipment can be processed according to customer requirements.

Technical Parameters

| Model | Power (HP) | Capacity(kg/h) | Weight(kg) | Size(mm) |

| SF50 | 0.75+2.2 | 250-350 | 550 | 1700×800×1000 |

| SF70 | 0.75+2.2×2 | 300-500 | 280 | 1900×900×1000 |

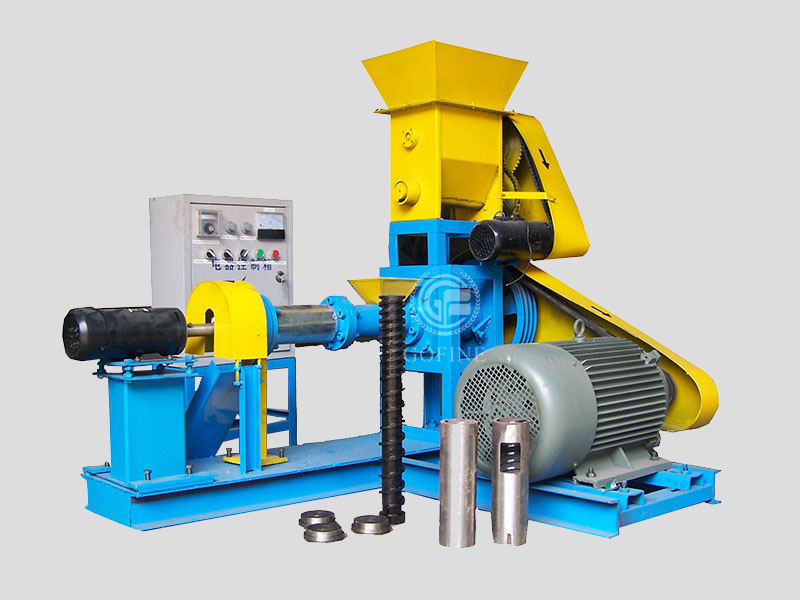

Product Pictures

Service Process

Pre-sales Service

1. Provide comprehensive technical and business consulting services.

2. Propose the most suitable solutions and equipment for customers.

3. Design and produce machines according to the special requirements of customers.

After-sales Service

1. Carefully check every process of the machine, quality first.

2. Assist customers in equipment infrastructure construction.

3. Dispatch engineers to install and debug equipment, and train front-line operators on site.

4. Regularly visit customers to solve production problems and provide technical support.

The feed counterflow cooler has a unique cooling mechanism. The cooling air moves in reverse with the high-temperature and high-humidity materials, so that the materials are gradually cooled from top to bottom, which avoids the surface cracking and core of the materials caused by the sudden cooling of the general vertical cooler. It has shortcomings such as difficulty in dissipating moisture and heat, but its cooling effect is better than existing similar domestic products. The cooled material temperature should not be higher than the outside temperature +5°C, and the precipitation rate should not be less than 3.8%. It plays a good role in producing high-quality pellet feed, extending the storage time of pellet feed, and improving economic benefits.

Videos:

Prev: Feed vibrating screening machine Next: Vertical feed countercurrent cooler

Related Products

Feed pellet packaging machine

Product Overview: Feed pellet packaging machine is a quantitative packaging equipment specially used for feed pellet materials. The fully automatic pellet packaging machine mainly includes the following parts: feeding device, metering device, packaging material supply device and packaging forming device. Its working principle is: the pellet material is transported to the metering device through the feeding device, the metering device weighs according to the preset parameters, and then the weigh…

Floating feed pellet machine

Product Overview: The Floating feed pellet machine is based on mechanical circular motion. The motor is used as the power to drive the belt pressure wheel to transmit to the main shaft and the flat die, so that the pressure wheel and the die plate are compressed and rubbed. The material is squeezed out from the flat die hole under the pressure of the pressure wheel, and the pellet feed is rolled out after being segmented by the cutter. It is packaged after natural cooling. This multifunctional …

Feed vibrating screening machine

Product Overview: Feed screening machine is a vibrating screening machine that uses the relative movement between bulk materials and the screen surface to make some particles pass through the screen holes, and classify materials such as sand, gravel, and crushed stone into different levels according to particle size. The screening process of the screening machine is generally continuous. After the screening raw materials are fed to the screening machine (referred to as the sieve), the materials…