Pet snack production line, pet food processing machine

Pet snack production line, pet food processing machine

Today, let's walk into this field full of technology and innovation and explore the secrets of pet snack equipment production line.

1. The importance of pet snacks

As a good friend of human beings, pets cannot grow up without high-quality snacks. Suitable pet food can not only meet their nutritional needs, but also improve their immunity, promote growth and development, and make them more lively and cute.

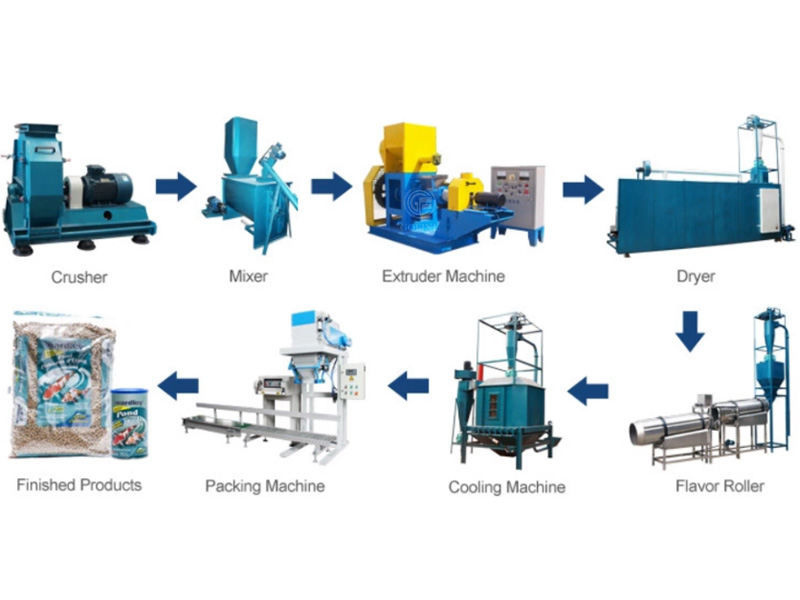

2. Composition of pet snack equipment production line

Raw material processing area

This is the starting point of the production line, where various high-quality grains, meats, beans and other raw materials are transported in. After screening, impurity removal and other processes, the purity of the raw materials is ensured.

Crushing equipment

The powerful crushing device grinds the raw materials into a suitable particle size for easy digestion and absorption by pets. Different raw materials may require different degrees of crushing to achieve the best nutritional effect.

Mixing and stirring area

In this link, various crushed raw materials are mixed and stirred according to scientific formula ratios. The precise metering system ensures that each ingredient can be accurately added to provide balanced nutrition for pets.

Granulating equipment

The mixed feed enters the granulator and is pressed into regular-shaped pellets. Granular feed is not only easy to store and transport, but also increases the interest of pets in eating.

Packaging area

Finally, the finished feed is automatically packaged into bags and prepared for shipment to various pet farms or pet stores.

3. Advanced technology helps produce high-quality pet food

Automated control

The pet food equipment production line adopts an advanced automated control system to achieve full-process automated operation from raw material input to finished product packaging. This not only improves production efficiency, but also reduces human errors and ensures the stability of feed quality.

Accurate measurement

The precise metering system can accurately control the amount of each raw material added to ensure the accuracy of the feed formula. This is essential to meet the special nutritional needs of pets.

Quality inspection

In the production process, strict quality inspection links are indispensable. By testing raw materials and finished feed, ensure that the feed meets relevant standards and the nutritional needs of pets.

4. Advantages of pet food equipment production line

Efficient production

The automation and continuous operation of the production line greatly improve production efficiency and meet the needs of pet breeding.

Balanced nutrition

Scientific formula and precise mixing and stirring ensure that pet snacks are nutritionally balanced, providing strong protection for the healthy growth of pets.

Stable quality

Advanced technology and strict quality control make the feed quality stable and reliable, and farmers and pet owners can use it with confidence.

Environmental protection and energy saving

Some pet food equipment production lines adopt environmental protection and energy-saving design, which reduces energy consumption and environmental pollution and meets the requirements of sustainable development.

5. Future Outlook

As people's requirements for the quality of pet food increase, pet food equipment production lines will continue to innovate and upgrade. In the future, we can expect more intelligent, efficient and environmentally friendly production lines to appear, providing better snacks for our good friends, pets.

In short, the pet food equipment production line is an important support for pet breeding. With advanced technology and efficient production capacity, it creates nutritious and high-quality rations for lovely pets. Let us pay attention to the development of pet food equipment production lines and contribute to the healthy growth of pets!

Prev: Best poultry feed pellet production line Next: 1-100T/H Duck feed pellet production line