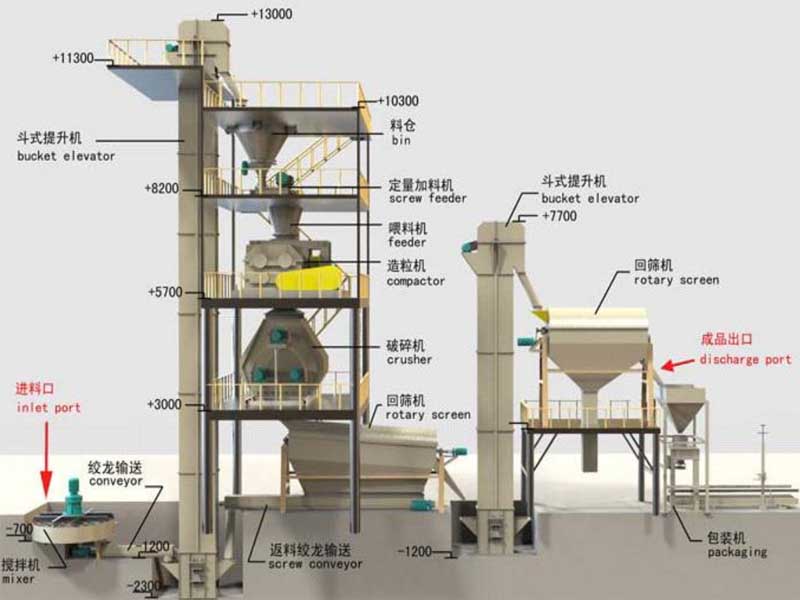

Bio-particle production process flow

Bio-particle production process flow

The detailed explanation of the biomass pellet manufacturing process is like a meticulous painting, and each process is like the brushstrokes on the painting, meticulous and precise. Starting from the raw material processing, the manufacturing of biomass pellets begins its magical journey.

Raw materials, which are the basis of biomass pellet manufacturing, include wood, straw, reeds, rice husks, etc. Each raw material contains the gift of nature. In the raw material processing link, workers use professional screening technology, just like chefs select ingredients carefully, to remove impurities and foreign matter, to ensure the purity of the raw materials. Then, the raw materials are broken into fine particles by the sharp blade of the crusher, and valuable components such as cellulose and lignin are separated, laying a solid foundation for subsequent processes.

The crushing and grinding link is a link that tests technology and equipment. Equipment such as mills, crushers, and pulverizers are like carving knives in the hands of artists, carving raw materials into fine powder. These powders are constantly refined in the roar of the machine, providing ideal raw materials for the granulation process.

Next, the drying link becomes a key step before granulation. Although natural drying is traditional, it is inefficient; modern hot air drying technology is like a magician's hand, instantly controlling the moisture content of the raw materials within an appropriate range and creating the best conditions for granulation.

Granulation is undoubtedly the core of the entire process. The granulator or pelletizer is like a mold in the hands of a skilled craftsman, compressing and squeezing the dried raw materials into full particles. These particles are born in the roar of the machine, shining with the wisdom and sweat of biomass pellet manufacturing.

The screening link is a test of the granulation results. Equipment such as screens or vibrating screens are like picky judges, screening out particles that meet the specifications and removing unqualified defective products. After this link, the quality of biomass pellets is further guaranteed.

Finally, the packaging link puts a perfect end to the biomass pellets. Workers skillfully pack the pellets into plastic bags, woven bags or paper bags, which facilitates the storage and transportation of the products. These packaged biomass pellets, like messengers of nature, deliver green energy to thousands of households.

Prev: What types of farm feed pellet machines are there? Next: Feed processing technology flow