Cattle feed production line to create efficient and effective feeding solutions

Cattle feed production line to create efficient and effective feeding solutions

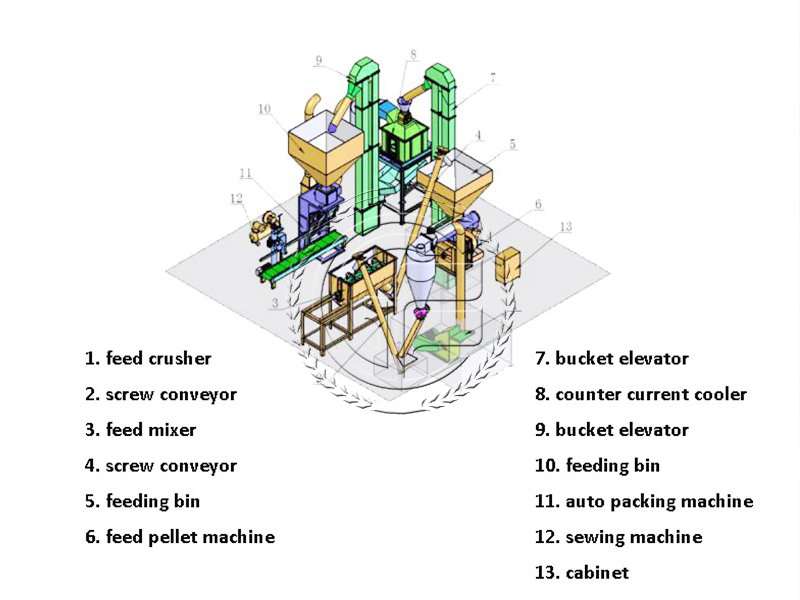

Under the global trend of large-scale farming and feed industry upgrading, efficient, stable and nutritionally balanced cattle feed production equipment has become the core of improving farming efficiency. Cattle feed production line integrates crushing, mixing, tempering, pelleting, cooling and other advanced processes in one, helping customers to achieve the whole process of automated production from raw materials to finished pellets, with a flexible configuration of 50-500 tonnes per day, to meet the diversified needs of small and medium-sized ranches to large-scale feed mills.

I. Core function and process

The cattle feed production line is designed for the nutritional needs of ruminants and can efficiently process:

Energy raw materials: corn, wheat, straw and other fibre materials are crushed and mixed;

Protein raw materials: Soya bean meal, rapeseed meal, urea and other precise ratios;

Nutritional additives: vitamins, minerals, probiotics evenly distributed.

Standardised process: raw material cleaning → coarse crushing → ingredients weighing → fine crushing → mixing and tempering → granulation / briquetting → cooling and sieving → finished product packaging, high particle hardness, dust rate <5%, to ensure the retention of nutrients and palatability.

Second, five core competitive advantages

High efficiency and energy saving, excellent production capacity

Adopting double-axis differential speed mixer + double-layer tempering device, the mixing uniformity CV≤5%, the tempering temperature is accurate to ± 2 ℃, the production efficiency is 40% higher than the traditional equipment;

Modular design supports flexible expansion of production capacity, reducing energy consumption of single line by 25% and saving more than 15% of production cost per ton of feed.

Intelligent control, stable quality

PLC + industrial computer dual control system, real-time monitoring of batching accuracy (error ≤ 0.3%), temperature, humidity and other 20 + parameters, data traceability;

Equipped with near infrared (NIR) rapid detection module, online analysis of protein, moisture content, to ensure that the nutritional indicators meet the standards.

Durable and environmentally friendly, safe and compliant

Core equipments (granulator, pulveriser) are made of wear-resistant alloy steel with ceramic coating, which extends the service life by 30% and reduces the failure rate to less than 1%;

Pulse dust removal + biological noise reduction design, dust concentration <10mg/m³, noise ≤ 80dB, in line with EU ATEX and FDA health standards.

Flexible adaptation to multi-form production

Can switch the production of 2-12mm diameter pellet feed, nutritional cubes or puffed feed to meet the needs of calves, dairy cows and beef cattle at different growth stages;

Supports the addition of molasses, oil and other liquid coating to enhance the energy density and flavour of feed.

Global Application Scenarios

Large-scale breeding groups: build self-sufficient feed production system and reduce outsourcing costs;

Regional feed processing plants: undertake substitute processing orders to expand the market share of cattle and sheep feed;

Agricultural cooperatives: using local straw and grain resources to produce low-cost roughage;

International project experience: the equipment has been exported to North America, the Middle East, Australia and other livestock-intensive areas, adapting to extreme environments such as high temperature and dryness, high humidity and high altitude.

Fourth, the whole chain service system

GOFINE machines provide full escort from planning to production:

Customised design: provide free 3D plant layout plan according to the characteristics of raw materials and capacity demand;

Technical training: remote guidance + on-site operation training to achieve skilled production within 7 days;

Global operation and maintenance: providing 48-hour emergency response and direct supply of spare parts.

Get free production line planning and trial production samples immediately!

Whether you are building a new feed mill or upgrading an existing production line, the cattle feed production line will help you win the market competition with intelligent equipment and localised service. Click on the website to book a consultation!

Keywords: Cattle feed production line|Ruminant feed equipment|Feed processing machinery|Automated feed production

Prev: Gofine Machinery sincerely invites you to the 2025 Egypt International Agricultural Exhibition! Next: Feed pellet packaging machine starts precise packaging