How to Choose the Right Animal Feed Equipment

How to Choose the Right Animal Feed Equipment

You can start from the following aspects to choose animal feed equipment:

1. Determine the scale of production

First, you need to clarify your production demand scale. If it is a small farm, the capacity of the required equipment can be relatively low; if it is a large feed processing plant, high-capacity equipment or pellet production line is required. For example, a small farmer may only need equipment with a production of several hundred kilograms per hour, while a large factory may need equipment with a production of several tons or even more per hour.

2. Consider the type of feed

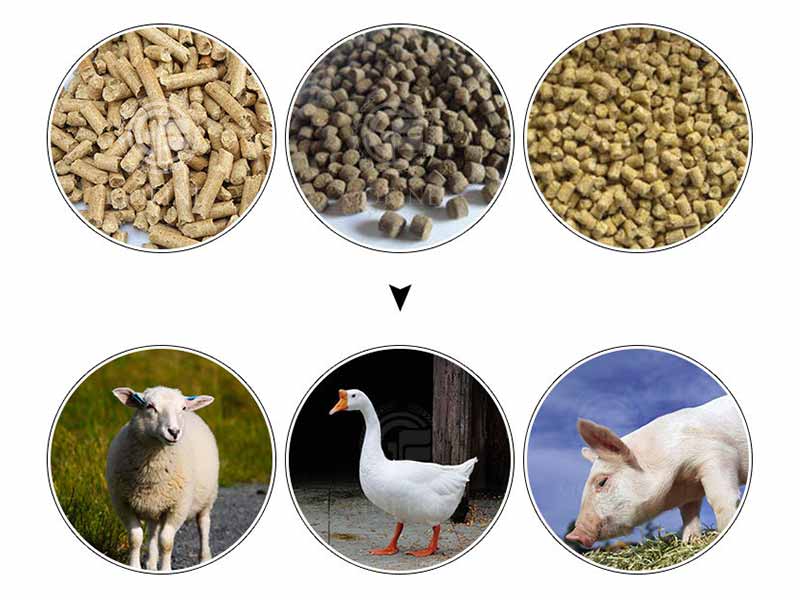

Different animals require different types of feed, such as pig feed, chicken feed, cattle feed, etc., with different particle sizes and ingredient requirements.

Powdered feed equipment: If the main production is powdered feed, the performance of the crusher and mixer should be considered. The crusher should be able to crush the raw materials to the appropriate particle size, and the mixer should ensure that the various raw materials are fully mixed and evenly mixed. For some powdered feeds of young animals, the raw materials need to be crushed finer to facilitate digestion and absorption.

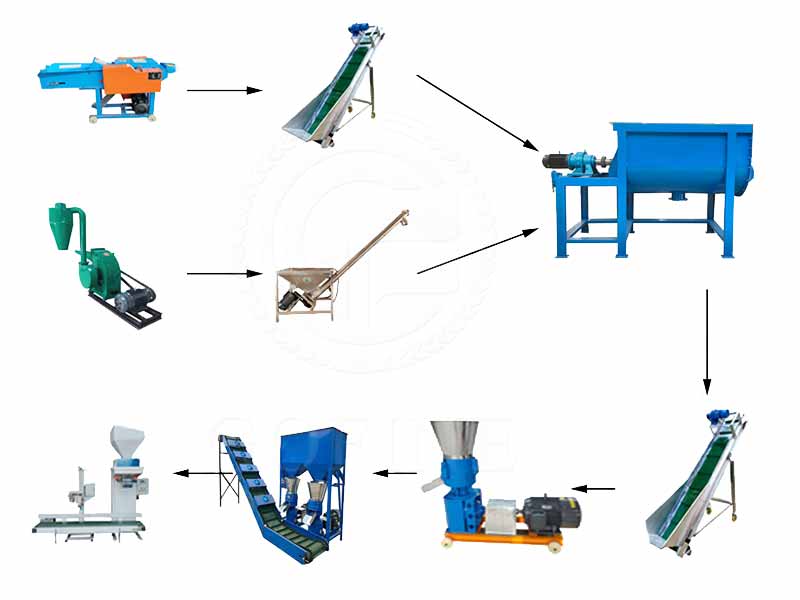

Pellet feed equipment: If pellet feed is produced, in addition to the crusher and mixer, a pellet machine is also required. The model and performance of the pellet machine directly affect the quality and output of the pellets. For pellet feed for aquaculture, harder pellets may be required to prevent them from spreading too quickly in the water.

3. Equipment quality and performance

The material of the equipment should be durable and corrosion-resistant. Generally speaking, equipment made of stainless steel has good corrosion resistance and is suitable for long-term use.

The equipment should have high precision and be able to accurately control the composition and proportion of the feed. At the same time, operational stability is also important to ensure the continuity and reliability of the production process.

According to your own needs and budget, choose equipment with different degrees of automation. Equipment with a high degree of automation can reduce manual operations, improve production efficiency and quality stability. Fully automatic production lines can realize the automation of the entire process from raw material delivery, crushing, mixing, granulation to packaging, greatly reducing labor intensity.

4. Brand and after-sales service

Choosing animal feed equipment from well-known brands usually has more guaranteed quality and more mature technology. You can understand the credibility of the brand by consulting industry reviews, user reputation, etc. Good after-sales service is an important guarantee for the long-term and stable operation of the equipment. It is necessary to understand the manufacturer’s after-sales service system, including after-sales response time, maintenance technology level, and spare parts supply.

5. Cost budget

According to your own budget range, choose equipment with high cost performance. Don’t just look at low-priced equipment, but consider the quality, performance and after-sales service of the equipment. Some higher-priced equipment may have obvious advantages in quality and performance, which can reduce maintenance costs and improve production efficiency in the long run. Consider the equipment’s energy consumption, replacement costs of wearing parts and other operating costs. Choosing energy-saving and efficient equipment can reduce production costs. Some advanced crushers use energy-saving motors, which can reduce energy consumption while ensuring the crushing effect.

Prev: Commercial cattle feed machine production line price Next: 3mm pellet feed equipment-poultry feed machine